Troubleshooting wiring networks is both a technical skill and an intuitive process. While theory provides the foundation, real-world diagnostics require methodical thinking, accurate observation, and the right tools. Whether youre working on a vehicle, a PLC system, or a domestic device, the ability to locate faults efficiently depends on your understanding of how circuits behave under both normal and abnormal conditions. This Golf Electronic Management Systems Wiring Diagrams Descriptions manualupdated for 2026 under http://wiringschema.comsummarizes the diagnostic procedures used by professionals in Diagrams Descriptions and beyond.

The first step in any diagnostic process is **observation**. Before touching a single wire, take time to understand the symptoms. Is the circuit completely dead, or does it behave intermittently? Does a fuse blow repeatedly, or does a component operate erratically? Each clue helps narrow down the possibilities. Skilled technicians gather this information before physical testing, because many electrical problems stem not from defective parts but from corrosion, vibration, or poor grounding.

Once symptoms are noted, the second step is **verification**. Always confirm the complaint. If a report says a light wont turn on, verify whether the issue lies in the bulb, switch, relay, or fuse. Use every sensesight, sound, touch, and even smellto identify signs of failure. Burn marks on insulation, a clicking relay, or the odor of overheated plastic may point directly to the root cause. Observation is data, and data drives decisions.

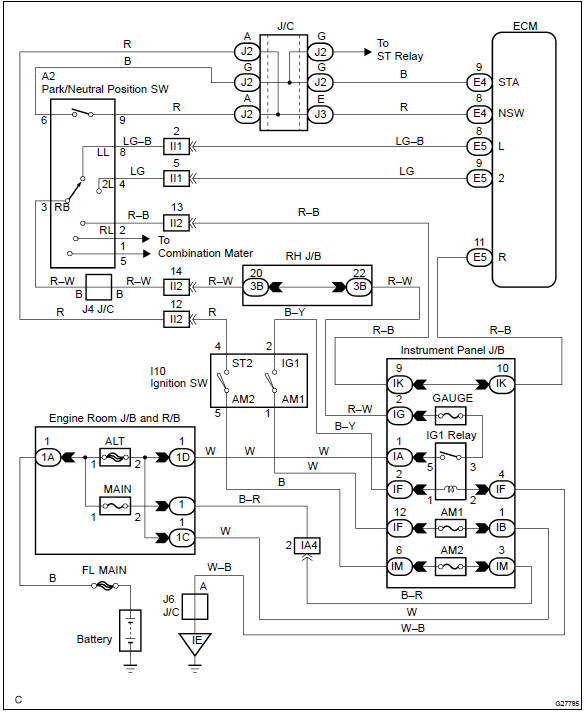

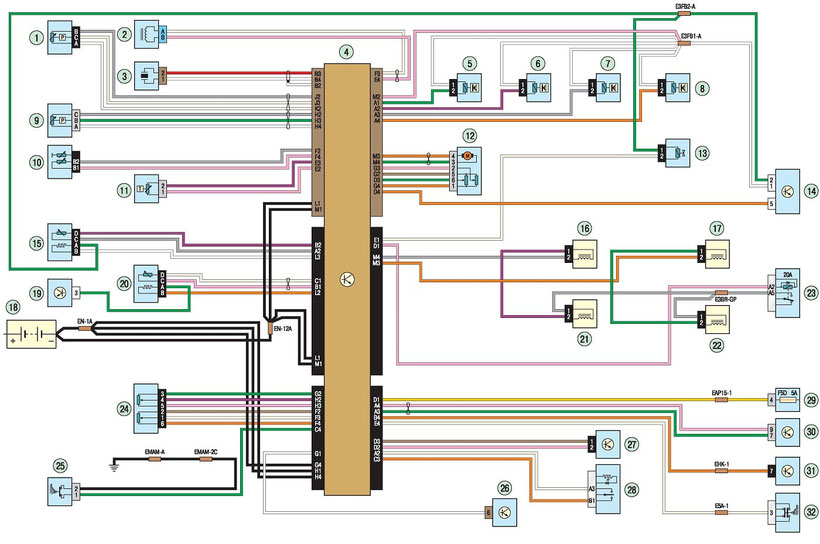

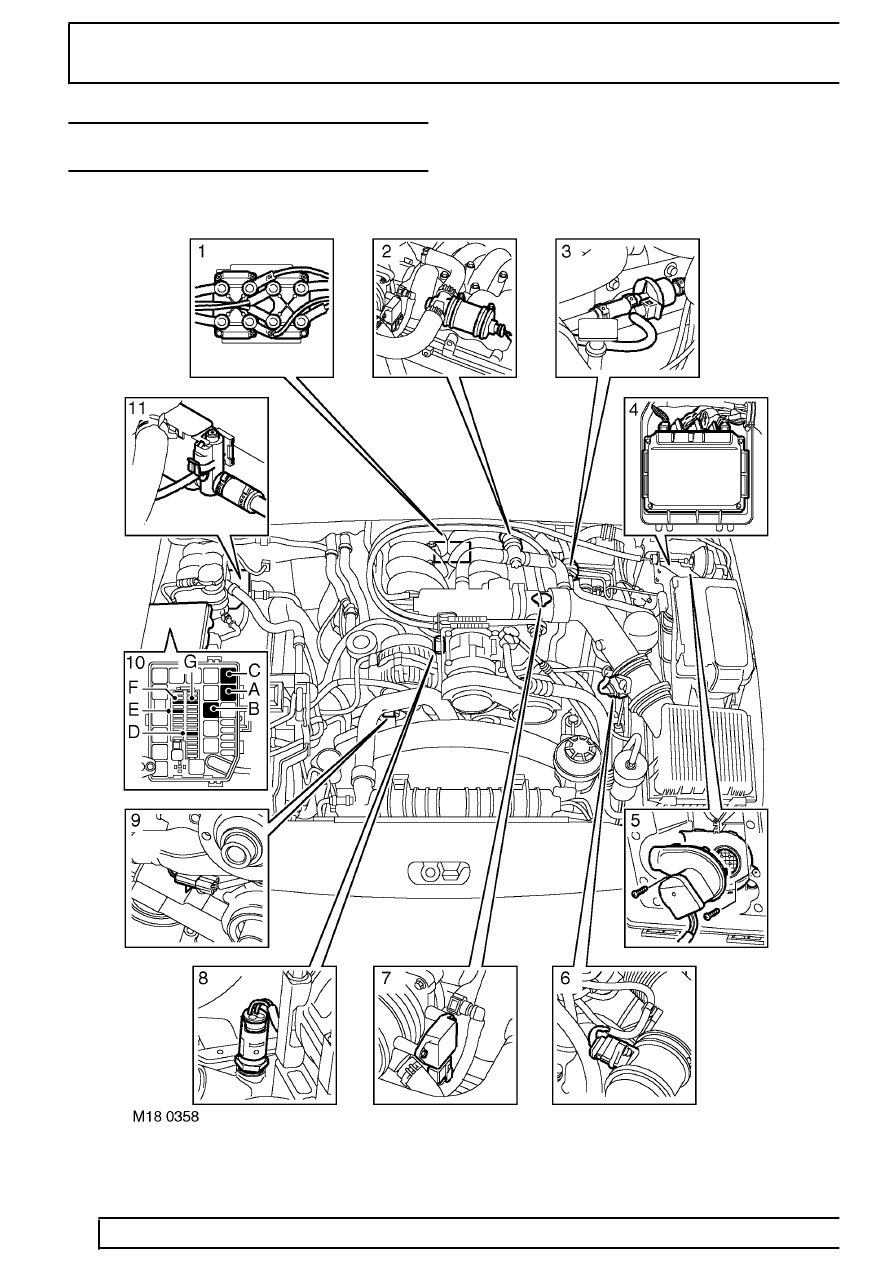

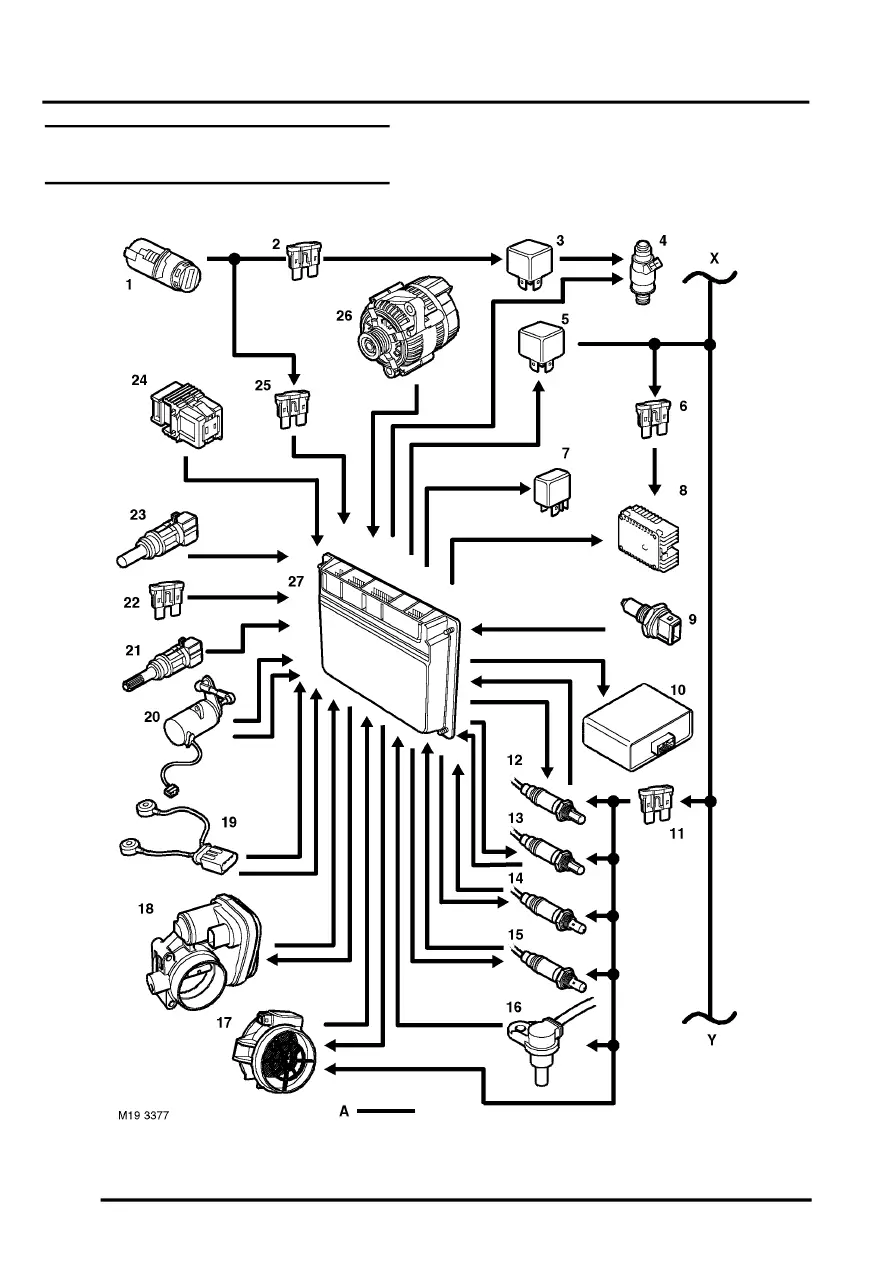

Next comes **isolation of the circuit**. Divide large systems into smaller test sections and evaluate each separately. Begin at the power source and move toward the load, measuring voltage at each stage. A sudden voltage drop or missing reading shows that the fault exists between the last known good point and the next. This logical progression avoids random part swapping and pinpoints faults with precision.

Using proper **test equipment** is critical. A digital multimeter (DMM) is your universal instrument, allowing measurement of voltage, resistance, and continuity. However, a static reading of 12 volts doesnt guarantee healthvoltage under load matters more. Thats why professionals perform **voltage drop tests**, measuring potential difference across connectors or wires while current flows. Even a 0.5-volt drop can reveal hidden resistance, dirt, or oxidation that disrupts performance.

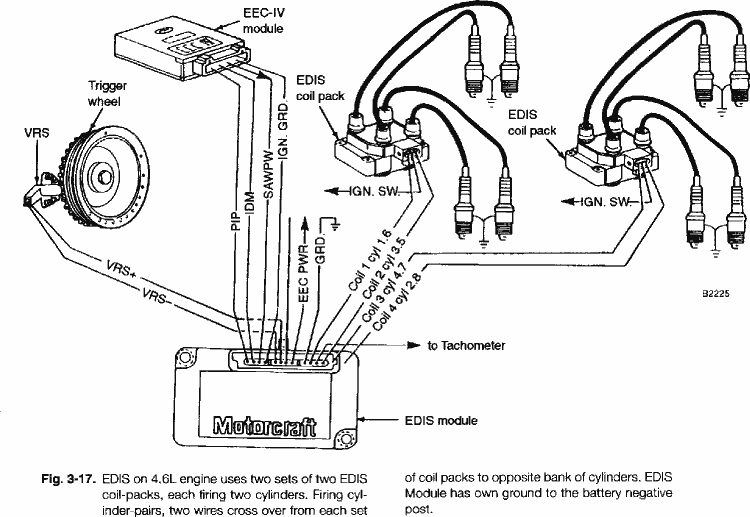

For advanced diagnostics, an **oscilloscope** becomes indispensable. It displays voltage as a waveform over time, revealing how sensors, data lines, and actuators behave dynamically. With it, you can verify if a PWM (pulse-width modulation) signal is clean, or if interference distorts communication. Mastering waveform reading takes practice, but it opens a window into the unseen world of electronic activitya skill every professional in Diagrams Descriptions should learn.

**Continuity testing** verifies whether current can flow freely through a conductor. Its a quick way to check for breaks or bad joints, but its not absolute proof of circuit integrity. A wire can pass a low-current continuity test and still fail under load due to corrosion or poor crimping. Combine continuity checks with voltage drop measurements for a complete diagnostic profile.

**Ground testing** is equally vital. Many mysterious faults trace back to weak or rusty grounds. Loose bolts, paint between contacts, or overloaded return paths can mimic sensor or communication failures. To test, measure voltage drop between the components ground and the negative terminal while active. Any reading above **0.1 volts** signals excessive resistance. Cleaning and protecting ground points with dielectric grease prevents future recurrence.

In circuits using relays, solenoids, or motors, sometimes your **ears and hands** are diagnostic tools too. A relay might click but fail internally because of burned contacts. A motor that hums but doesnt spin could have power but insufficient torque due to mechanical binding or low voltage. Dont underestimate the simplicity of sensory checksthey often lead to quicker solutions than complex instruments.

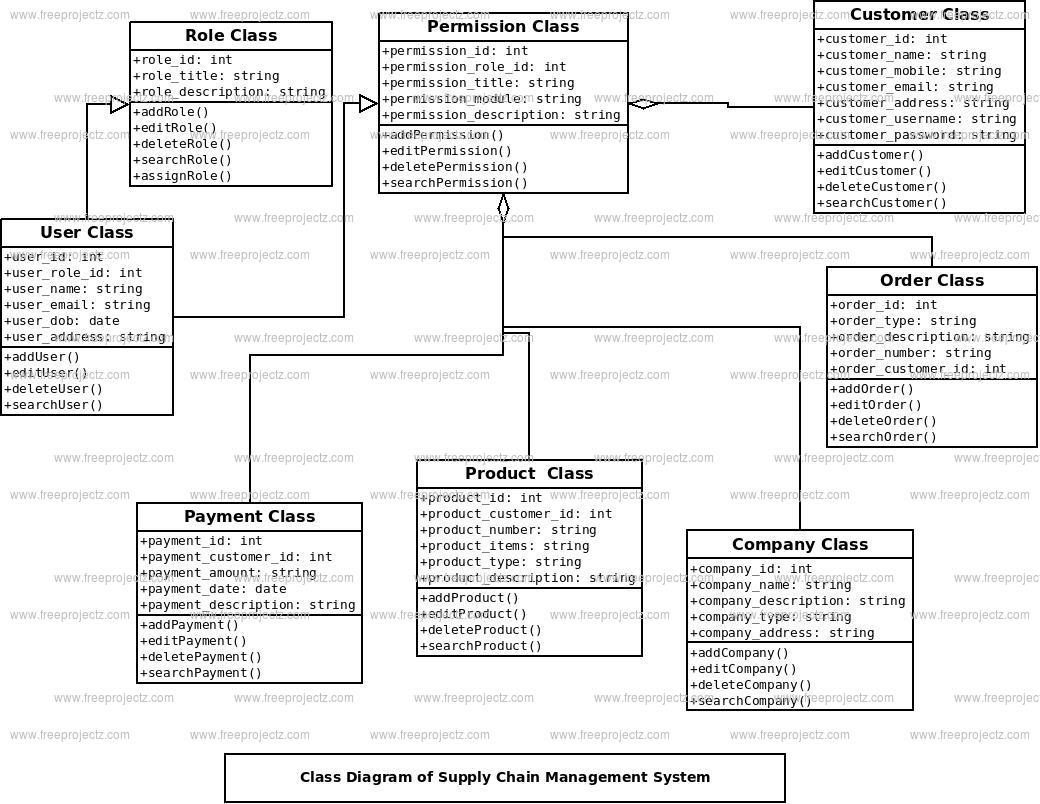

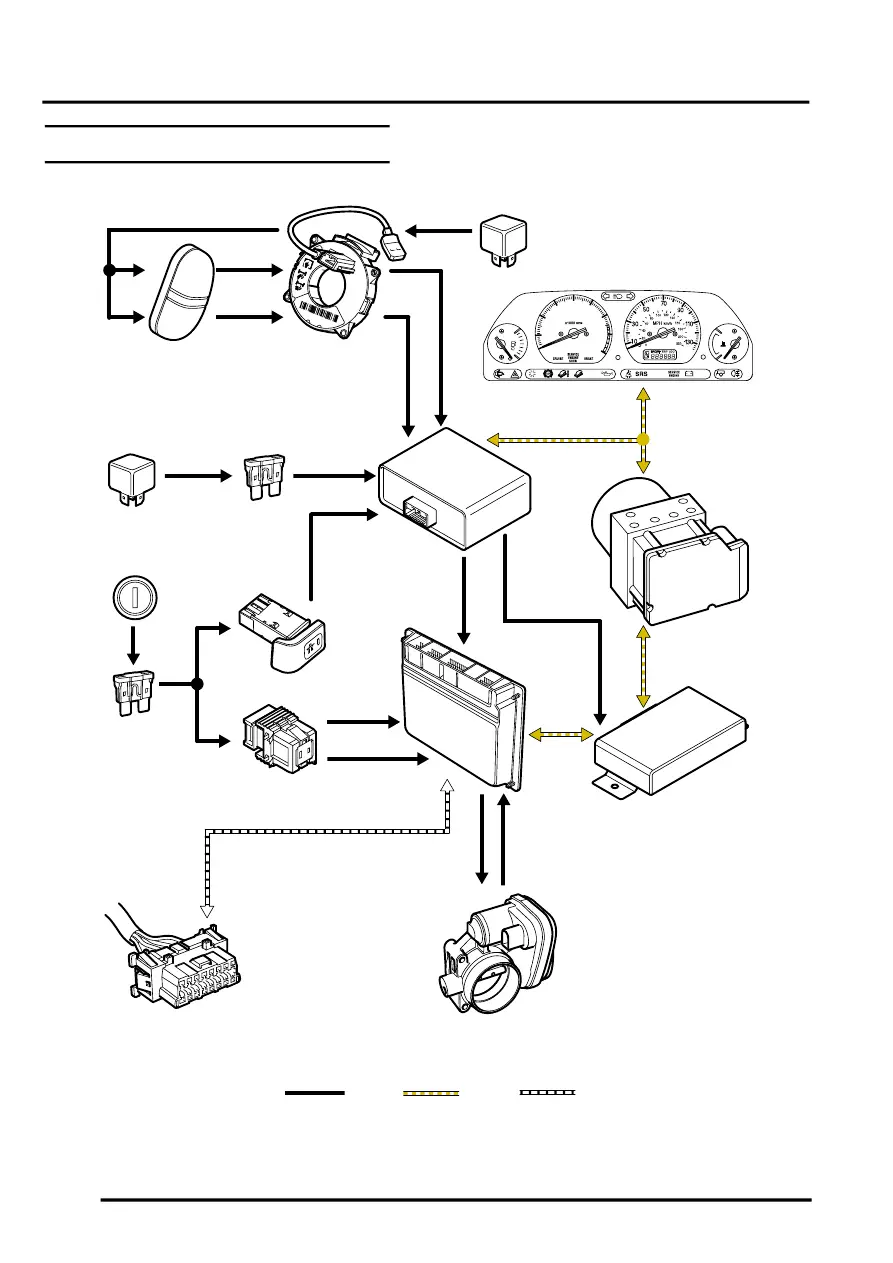

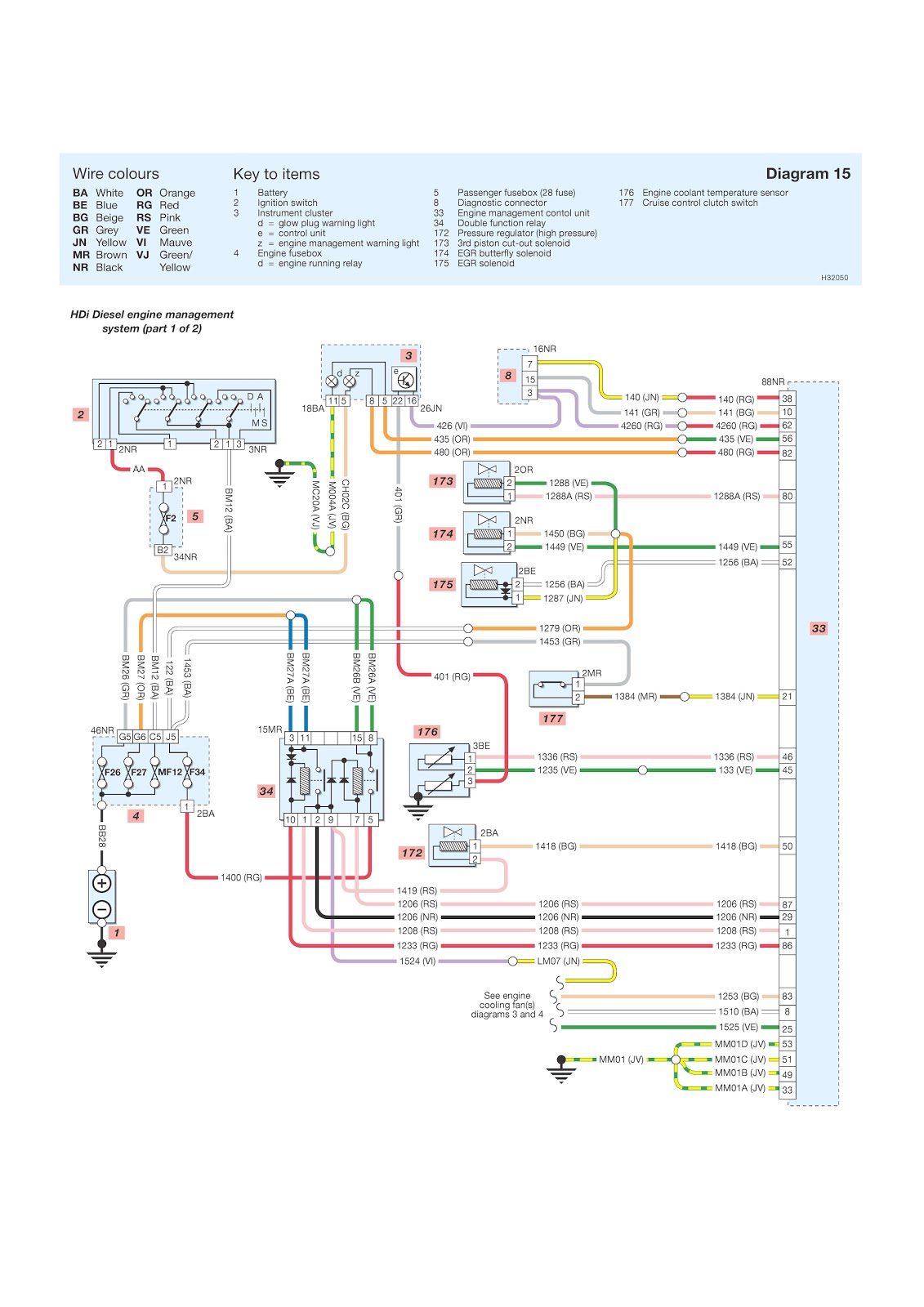

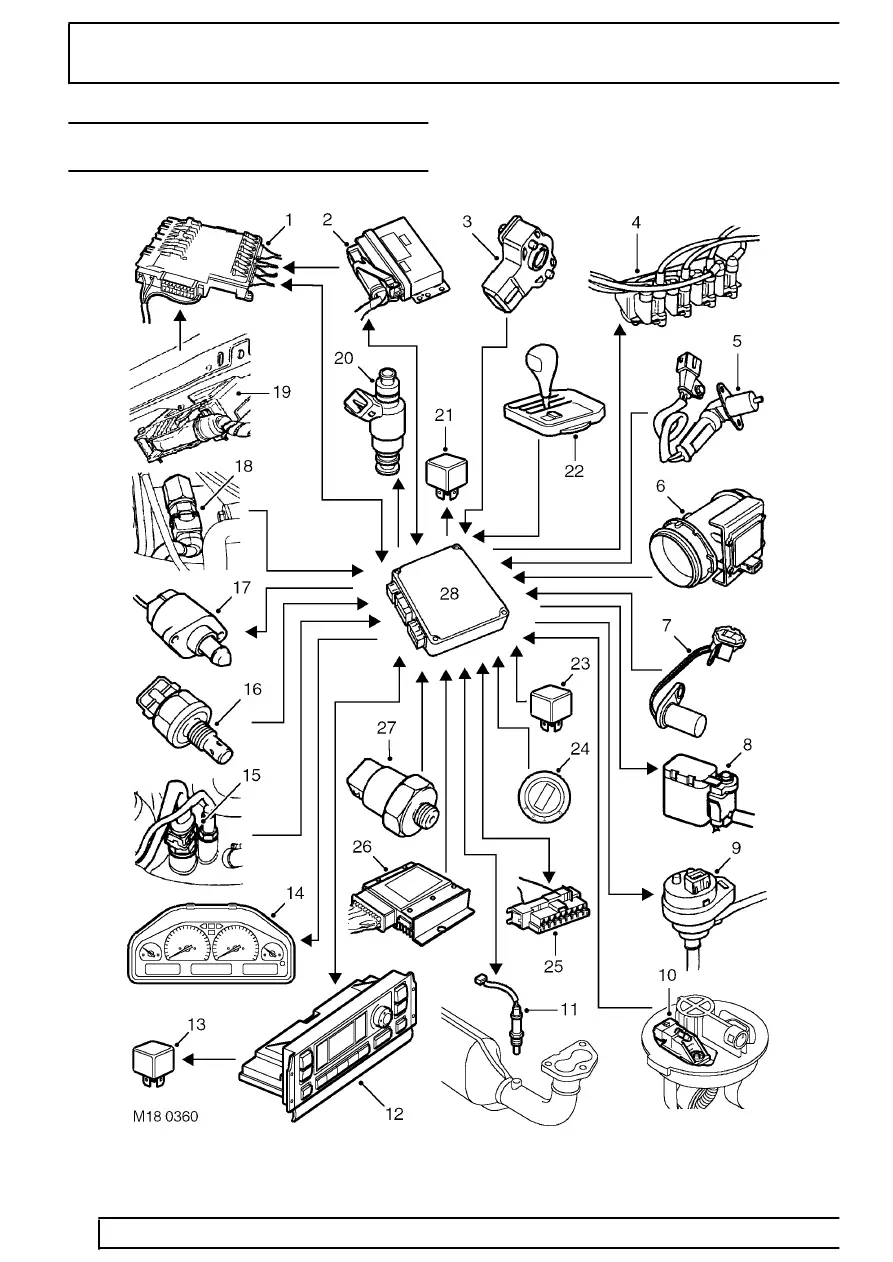

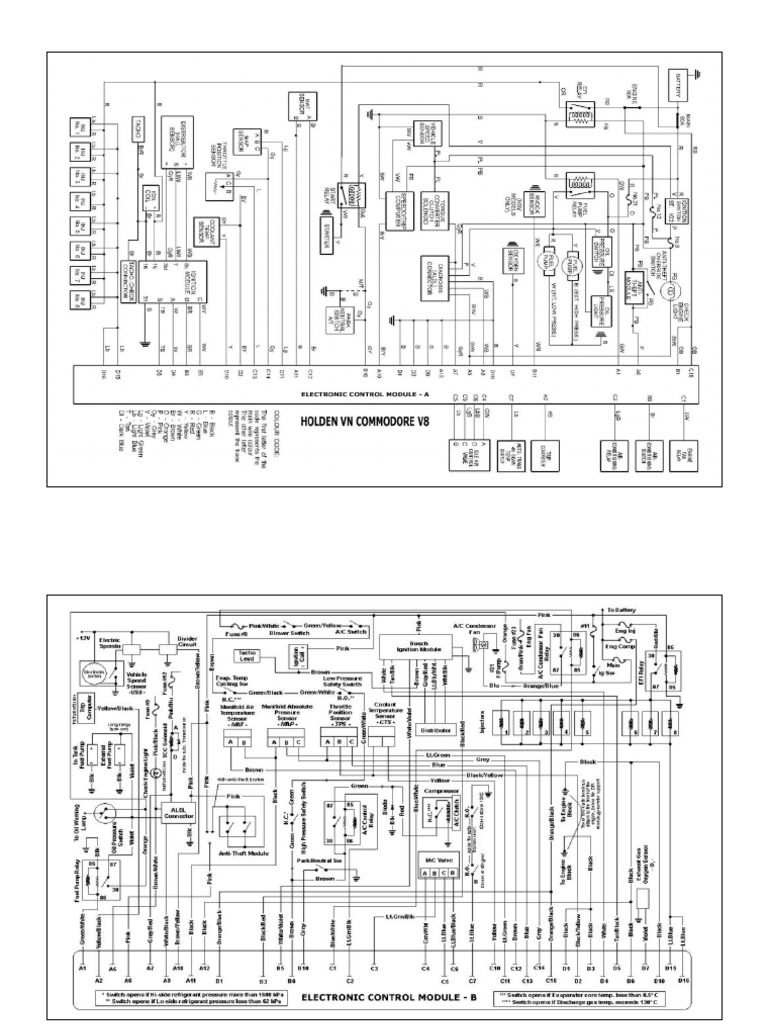

Documentation is your greatest ally. Always consult **wiring diagrams** and schematics before testing. They show how circuits connect, where protection devices are located, and how current flows between sections. Comparing real-world readings to diagram expectations exposes faults instantly. Professionals treat schematics like roadmapsthey show direction, not just location, and help connect cause with effect.

An advanced yet cautious method is **substitution testing**replacing a suspected faulty component with a known-good one. If the issue disappears, the original part was bad. But use this only when confident, since swapping components in sensitive electronic systems can introduce new errors or damage.

Every diagnostic process concludes with **verification and prevention**. After a repair, always retest to confirm operation, then determine *why* the failure occurred. Was it mechanical wear, corrosion, overload, heat, or a design flaw? Taking preventive measuresrerouting wires, reinforcing insulation, tightening groundsprevents the same issue from returning.

Effective troubleshooting combines logic, observation, and technical understanding. Each measurement builds a clearer picture of circuit behavior. With experience, technicians develop whats known as *electrical intuition*the ability to sense where faults lie before testing. Its not guesswork; its experience guided by knowledge.

By following structured procedures as outlined in Golf Electronic Management Systems Wiring Diagrams Descriptions, you transform trial-and-error into predictable, efficient diagnosis. Wiring diagrams stop being static imagesthey become **interactive maps of cause and effect**. In the end, the true skill of an electrical specialist isnt in changing parts; its in understanding how the system thinks, acts, and recovers. Thats the essence of professional troubleshootingmastered and shared globally through http://wiringschema.com in 2026, built upon decades of engineering expertise from Diagrams Descriptions.

/Page-3858001.png)

.gif)