Across todays automation networks, input and output elements form the critical link between the real environment and electronic logic. They translate real-world phenomenatemperature, force, movement, illumination, or chemical compositioninto signals that controllers can interpret and respond to. Without this conversion, automation would be ineffective and unresponsive. Understanding how these devices operate, and how they collaborate, is crucial for anyone designing or troubleshooting electrical and mechatronic systems.

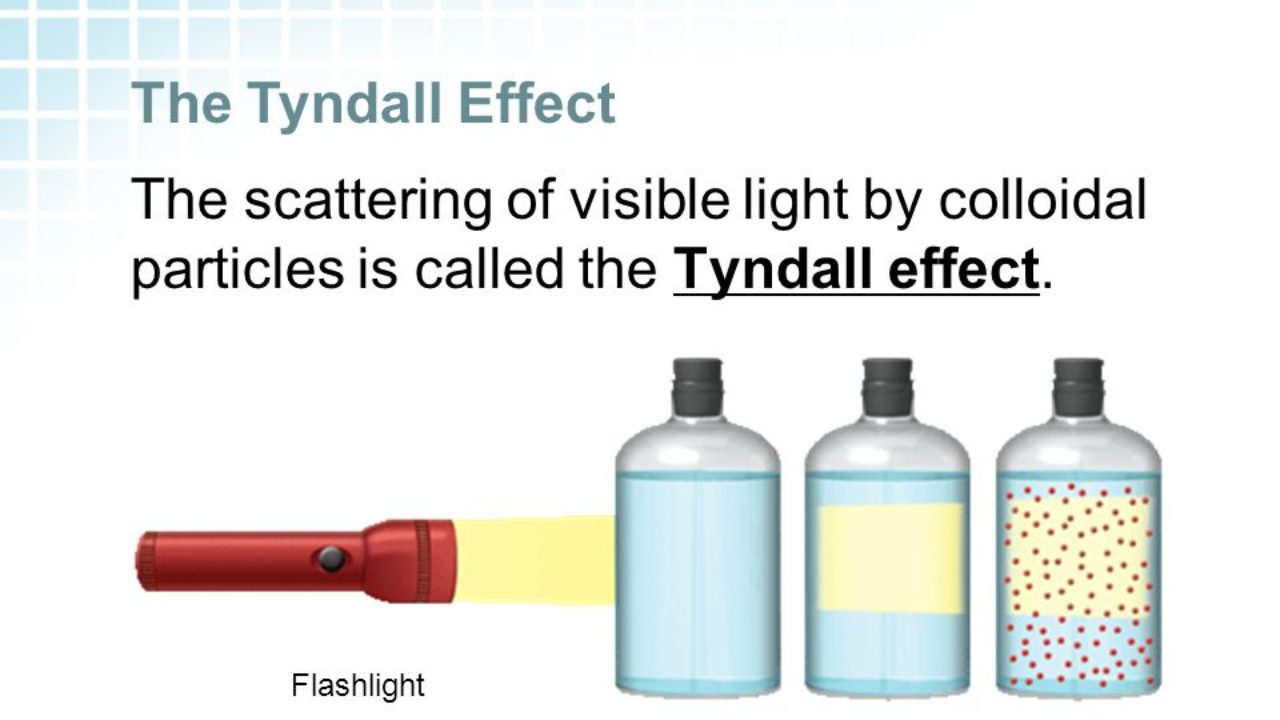

A measuring device is a component that detects a physical quantity and transforms it into an electrical signal. Depending on the application, this could be frequency output. Behind this simple idea lies a complex chain of transduction and calibration. For example, a temperature sensor may use a thermistor whose resistance changes with heat, a strain transducer may rely on a strain gauge that deforms under load, and an optical sensor may use a photodiode reacting to light intensity. Each of these transducers turns physical behavior into usable electrical information.

Sensors are often categorized as active or passive. Powered sensors require an external supply voltage to produce an output, while self-powered sensors generate their own signal using the energy of the measured variable. The difference affects circuit design: active sensors require regulated power and noise suppression, while passive types need amplification or compensation for stable readings.

The performance of a sensor depends on accuracy, resolution, and response time. Engineers use signal conditioning circuits to refine raw data before they reach the controller. Proper earthing and EMI protection are also essentialjust a few millivolts of interference can produce false measurements in high-sensitivity systems.

While sensors provide feedback, drivers perform physical response. They are the motion sources of automation, converting electrical commands into movement, heat, or fluid control. Common examples include electric motors, electromagnetic plungers, fluid regulators, and resistive heaters. When the control system detects a deviation from target, it sends control signals to actuators to restore balance. The accuracy and timing of that response defines system stability.

Actuators may be electromagnetic, hydraulic, or pneumatic depending on the required force. DC and AC motors dominate due to their precise response and easy integration with electronic circuits. Stepper motors and servomotors offer accurate angular control, while linear actuators convert rotation into push-pull movement. In high-power systems, electromagnetic switches serve as secondary control devices, switching large currents with minimal control effort.

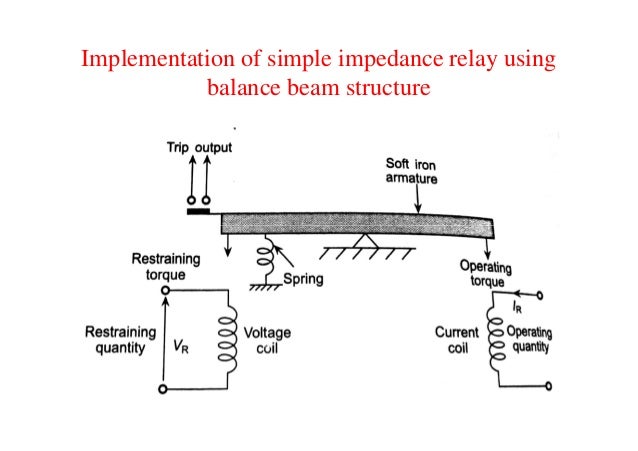

The interaction between detection and control forms a closed control system. The controller continuously reads sensor data, compares it with setpoints, and modifies response accordingly. This process defines closed-loop control, the foundation of modern mechatronicsfrom simple thermostats to complex robotics. When the sensor detects that the system has reached the desired condition, the controller reduces actuator output; if conditions drift, the loop automatically compensates.

In advanced applications, both sensors and actuators communicate via digital networks such as CAN, LIN, Modbus, or IO-Link. These protocols enable real-time data exchange, built-in diagnostics, and even remote configuration. Smart sensors now include microcontrollers to preprocess signals, detect faults, and transmit only meaningful datareducing communication load and improving reliability.

Integration also introduces new challenges, especially in timing and accuracy management. If a sensor drifts or an actuator lags, the entire control loop can become oscillatory. Regular calibration using reference standards ensures measurement reliability, while actuator verification keeps motion consistent with command. Many systems now include self-diagnostics that adjust parameters automatically to maintain accuracy.

Safety and redundancy remain essential. In aerospace, medical, and process control, multiple sensors may monitor the same variable while paired actuators operate in parallel. The controller validates data to prevent erroneous actions. This approachknown as redundant architectureensures that even if one component fails, the system continues operating safely.

From simple switches to miniaturized micro-sensors, sensing technology has evolved from passive elements to self-aware instruments. Actuators too have advanced, now including position feedback and built-in diagnostics. This fusion of sensing and action has transformed machines from reactive systems into adaptive, self-regulating platforms.

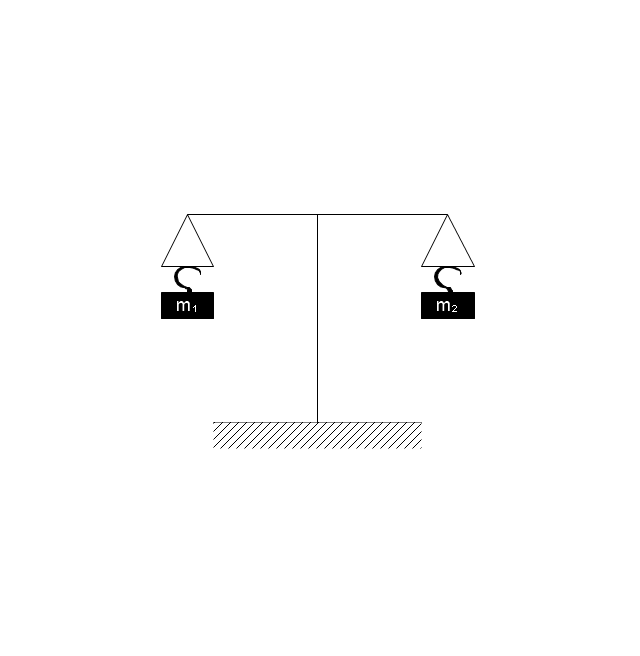

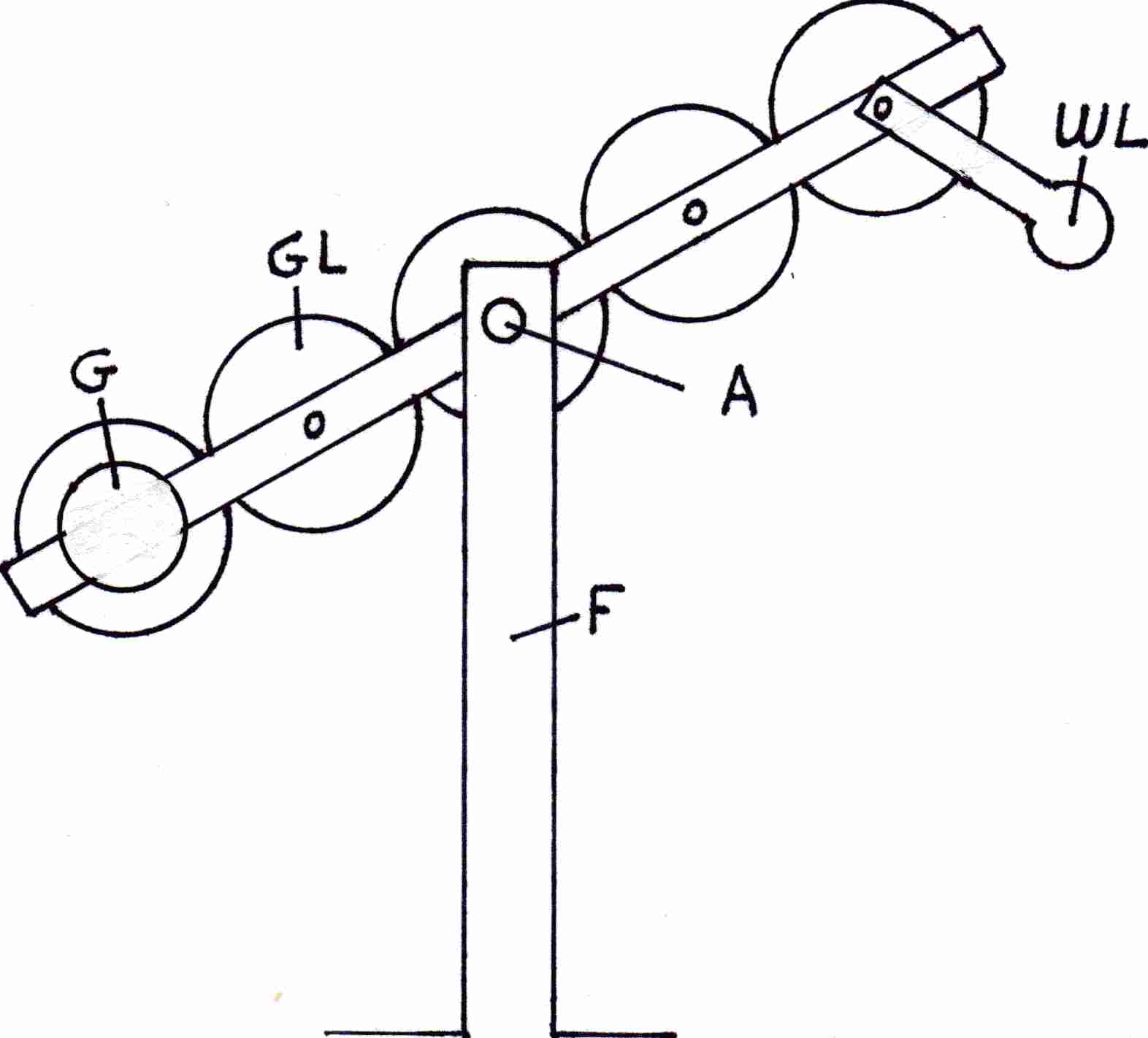

Ultimately, the connection between measurement and motion defines the capability of any control system. Sensors perceive reality, actuators shape it. Between them lies the controllerthe brain that interprets, decides, and commands. When all three work in harmony, the result is a self-regulating system built on precision. That is the essence of modern automation and the theme explored throughout Labelled Diagram Of Simple Chemical Beam Balance (Beam Balance, 2026, http://wiringschema.com, https://http://wiringschema.com/labelled-diagram-of-simple-chemical-beam-balance/WIRINGSCHEMA.COM).