Within every engineered wiring network, the layout of conductors and harnesses determine more than just aestheticsthey directly affect system stability, durability, and efficiency. A well-designed cable harness is the structural backbone of a circuit, uniting dozens or thousands of conductors into a single organized network that carries power and information efficiently. Proper cable management ensures that the intended circuit layout functions as designed under vibration, heat, or stress.

A bundled wire system is an assembly of wires, connectors, and protective components that groups multiple circuits into a manageable form. Its goal is to organize and protect conductors while minimizing clutter and assembly effort. Instead of routing loose wires separately, technicians use harnesses to group related signals, simplifying production, maintenance, and troubleshooting. In vehicles, aircraft, and industrial machines, harnesses mean the difference between a clean, reliable installation and a chaotic web of faults.

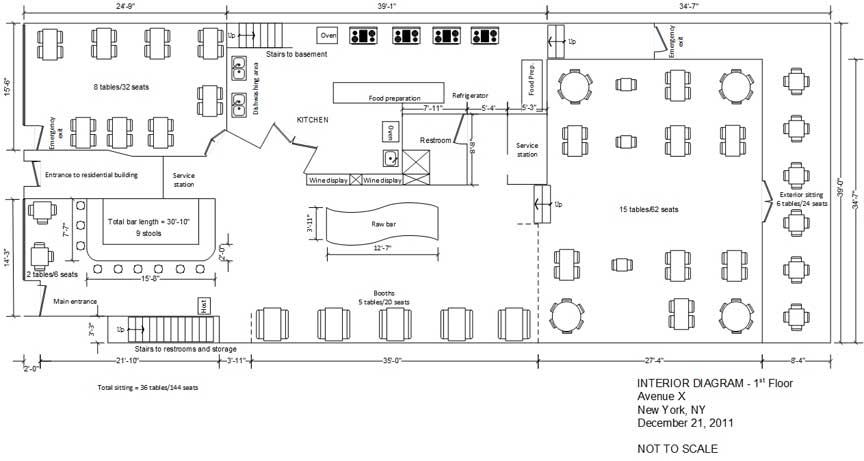

Designing a harness begins with a logical layout plan. Engineers review circuit blueprints to determine which components connect and how far apart they are. Each wire must follow the most logical and shortest route while avoiding hazard zones or mechanical stress. Modern CAD-based systems now convert 2D schematics into 3D harness models that fit perfectly into a chassis or enclosure. These models ensure easy assembly and maintenance.

The selection of conductor size and coating depends on current, voltage, and environment. In automotive and aerospace systems, cross-linked polyethylene (XLPE) or PTFE insulation are preferred. For dynamic systems, multi-strand conductors with elastic insulation withstand repeated motion. When cables are grouped closely, derating factors must be applied to prevent overheating.

Protection and organization come from sleeving, conduit, and lacing. Woven mesh sleeves provide flexibility and abrasion resistance, while plastic or metal conduit adds rigidity and shielding. binding tapes and harness wraps keep bundles compact. Heat-shrink tubing seals joints and repels moisture. In environments with high EMI, braided shields or foil wraps block unwanted noise. Every technique must balance strength, budget, and flexibility.

Connectors and terminals form the interface between harness and device. Their reliability determines system longevity and performance. Corrosion-resistant contacts extend life, while silicone gaskets prevent dust and humidity ingress. Proper crimping is critical: a loose crimp causes contact resistance and arcing, while an over-crimp damages strands. Professionals perform mechanical and electrical verification before final installation.

Cable routing must consider strain relief and motion. Cables should follow controlled bend radii rather than tight angles, leaving room for vibration and temperature shifts. Clamps and grommets prevent chafing at panel or frame edges. In dynamic applications such as robot arms and mobile assemblies, harnesses are engineered for controlled flexing to prevent fatigue.

Labeling and identification are essential for future maintenance. Every wire or connector must have a unique code or color matching the technical documentation. This allows technicians to diagnose problems accurately, even in large assemblies. Heat-resistant labels or laser-etched sleeves ensure long-term readability.

Cable management doesnt end after installation. During commissioning and service, technicians must verify that bundles remain tight and free from aging and abrasion. Over time, vibration, UV, and chemicals degrade insulation. Regular inspection detects cracks, discoloration, or loose fasteners, ensuring continued safety.

In large installations such as control rooms, vehicles, or automation facilities, sectional cable architecture is now preferred. Instead of one large assembly, modular segments connect through interface connectors. This approach reduces downtime and improves flexibility, allowing damaged sections to be swapped without rewiring.

Proper cable management reflects professional discipline and foresight. A clean, organized harness improves heat dissipation, reduces vibration damage, and enhances safety. It also demonstrates design maturity: understanding that reliability comes not only from electrical theory but also from physical workmanship.

In conclusion, a wiring harness is more than a bundle of wires. It translates schematic intent into real operation. Proper routing and assembly discipline ensure that power and signals reach their destinations safely and efficiently. Its both an engineering science and an art, where organization and precision transform complexity into reliability.