Contemporary wiring networks have grown far beyond simple switches and relays. They now include microcontrollers, sensors, and communication buses, all linked via layered wiring systems. Diagnosing faults in such systems requires more than guesswork or observationit demands a logical process supported by accurate tools. Without a systematic approach, troubleshooting quickly turns into guesswork that drains efficiency and reliability.

Diagnostics is the systematic study of system behavior. It observes how a system performs under design conditions compared to reality. Success begins by establishing reference points: voltage, waveform, or logic state. Each data point captured offers clues that, when combined, reveal the precise fault origin.

### **1. Fundamental Tools**

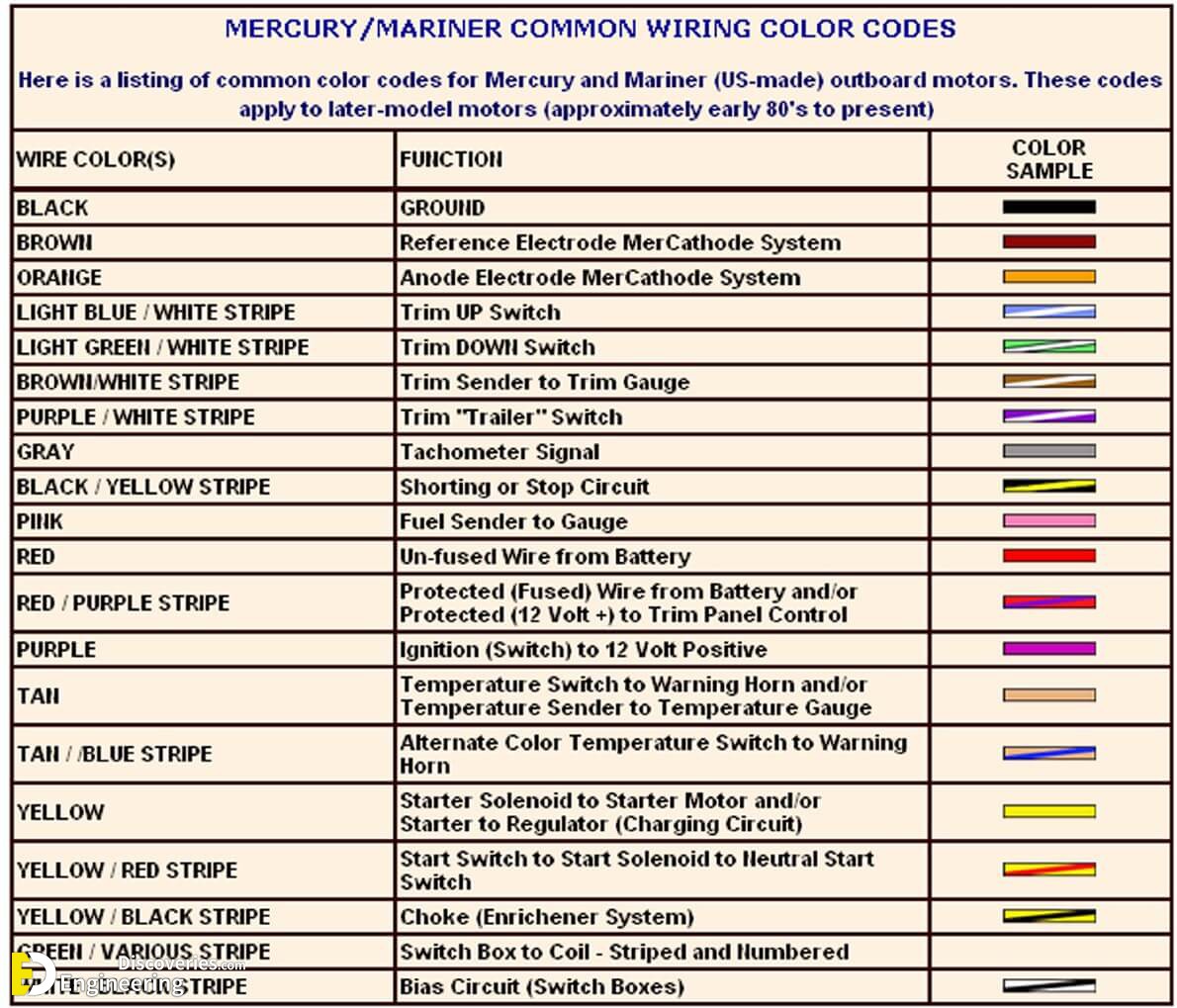

The starting point of every diagnostic process is the universal measuring instrument. It measures the three key electrical quantities with precision and speed. Whether youre checking power rails, earth paths, or resistor values, the DMM provides the first layer of confirmation. Its beeper and forward-bias tests quickly expose broken links or polarity faults.

The oscilloscope extends measurement into the time domain. It reveals how voltage changes with time, displaying pulses, oscillations, and switching behaviors. For digital control or analog modulation, oscilloscopes visualize timing errors and instability. Multi-channel scopes can compare input and output to assess propagation delay or synchronization.

Clamp meters measure current without breaking circuits. They use magnetic induction to detect flow through conductors, ideal for energized installations. Modern DC-capable models reveal startup surges and parasitic draws that static tests may miss.

### **2. Advanced Diagnostic Instruments**

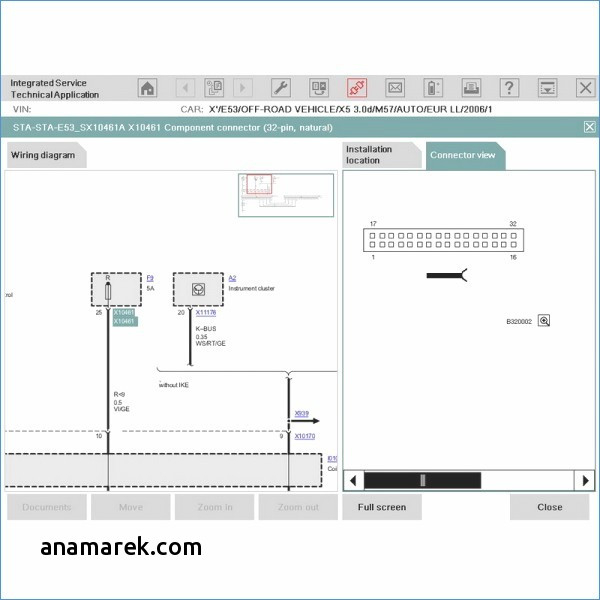

When basic tools arent enough, technicians turn to specialized analyzers and testers. Logic analyzers capture multi-line digital protocols, translating binary signals into human-readable data. This is vital when controllers exchange information and simple measurements cant explain failures.

Meggers apply high voltage to detect hidden conductive paths. In critical systems, this prevents arcing, shorting, or fire.

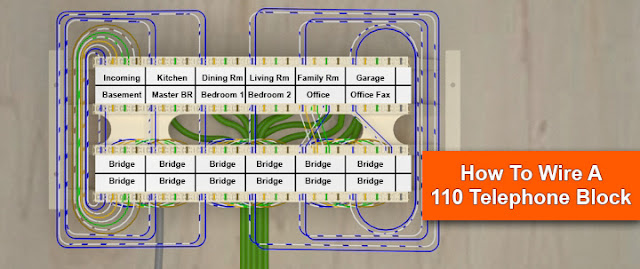

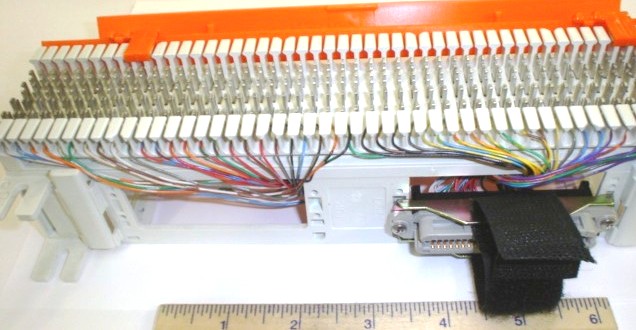

Cable analyzers locate breaks, impedance changes, or shorts. Theyre indispensable for long harnesses, shielded lines, and fiber optics.

At component level, precision analyzers measure electrical parameters with high accuracy. This detects connector contamination. Thermal cameras visualize temperature anomalies, instantly exposing loose joints, overloaded wires, or hidden shorts.

### **3. Measurement Strategy**

Tools mean little without method and order. Effective troubleshooting follows a repeatable workflow:

- **Visual Inspection:** Check connectors, insulation, and routing. Over half of faults are found visually.

- **Power & Ground Verification:** Confirm voltage supply and low resistance returns. Voltage drops cause most failures.

- **Signal Analysis:** Observe waveform shapes and timing during real operation.

- **Comparative Testing:** Measure against known-good systems.

- **Functional Simulation:** apply test loads safely to confirm repairs.

Record all observations. Documentation creates traceable knowledge, turning isolated measurements into trend data.

### **4. Safety and Calibration**

Safety ensures accuracy. Before testing, check insulation and tips. Calibrate instruments regularly to avoid misleading data. Always respect safety categories: never use a CAT II tool on CAT IV circuits. For high-voltage or floating circuits, use specialized isolation accessories.

### **5. Data Integration and Modern Trends**

Diagnostics is becoming digitally connected. Wireless multimeters and smart oscilloscopes stream data directly to the cloud. This enables real-time supervision and automated alerts. Robotized diagnostic benches now perform hundreds of tests per second, ensuring consistency and reproducibility. Combined with AI-assisted analytics, they predict weak points before failures occur.

### **6. The Human Element**

Despite automation, the human mind remains irreplaceable. Instruments display data, but experience interprets meaning. Skilled engineers correlate symptoms, readings, and history. They know that a weird trace may be a symptom, not the root cause. Effective diagnosis combines reasoning with field sense.

Ultimately, the goal is not just to collect data, but to understand. The right tools amplify insight, turning electrical behavior into a readable story. Mastering measurement transforms chaos into claritythe essence of true technical expertise.